Beam Bridges: A Structural Marvel of Simplicity and Strength

Author: MIDASoft

Publish Date: 11 Oct, 2023

|

Summary: Beam bridges, also known as girder bridges, are one of the most common and straightforward types of bridges found worldwide. Despite their apparent simplicity, they play a crucial role in our transportation infrastructure, safely carrying vehicles and pedestrians across rivers, valleys, and highways. This article explores beam bridges' design, construction, and key features, shedding light on the science behind their stability and strength. |

What are Beam Bridges?

A beam bridge consists of one or more horizontal beams supported at their ends by piers or abutments.

The concrete elements may be reinforced, pre-tensioned, or post-tensioned. Modern bridges include girder, plate girder, and box girder bridges, all types of beam bridges.

Types of construction could include having many beams side by side with a deck across the top of them, to a main beam on either side supporting a deck between them. The main beams could be I-beams, trusses, or box girders. They could be half-through or braced across the top to create a through bridge.

Components of a Beam Bridge

Beam Bridge - Beams (Girders)

The primary load-bearing elements of a beam bridge are the beams themselves, which run longitudinally across the span. These beams can be made of various materials, including wood, steel, concrete, or a combination of these. The choice of material depends on factors such as span length, expected load, and environmental conditions.

Beam Bridge - Supports

Beam bridges rely on supports, which can be piers or abutments, to bear the load of the beams and transfer it to the ground. Piers are vertical columns or posts built in the water or on the ground beneath it, while abutments are solid supports at the ends of the bridge.

Beam Bridge - Deck

The deck is the surface that vehicles and pedestrians travel on. It is usually constructed on top of the beams and provides the functional aspect of the bridge. The deck can vary in materials and design, depending on the bridge's purpose and location.

Beam Bridge - Substructure

The substructure includes all the elements below the deck that help support and distribute the load. This includes the pier cap, pier, pier, pile cap, pile, and abutment.

Picture 1: Concrete Bridge

Beam Bridge Design Principles

- Bending and Compression Forces:

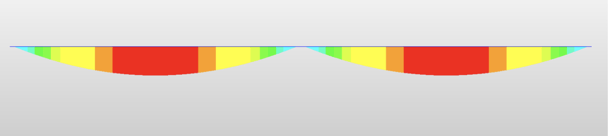

The primary forces acting on a beam bridge are bending and compression. When a load, such as vehicles or pedestrians, applies force to the bridge deck, the beams bend, and the top of the beam is in compression while the bottom is in tension. Engineers design beam bridges to withstand these forces safely by selecting appropriate materials and dimensions. However, depending on the methodology of construction, the forces in the girder can be reversed.

Figure 1: Bending Moment Diagram of a simple supported beam bridge

-

Span Length:

The length of a beam bridge's span is a critical factor in its design. Shorter spans can be achieved with simpler, single-span bridges, while longer spans may require multiple spans or more sophisticated engineering solutions. This design distributes the load primarily through bending and compression forces, making beam bridges suitable for spanning relatively short distances.

- Material Selection:

The choice of material depends on several factors, including load-bearing capacity, environmental conditions, and cost. Steel and concrete are commonly used materials for their strength and durability. Concrete is generally used for short spans and steel for longer spans.

- Load Analysis:

Engineers must calculate the maximum expected loads the bridge will encounter, including traffic loads, live loads (such as pedestrians and vehicles), and environmental factors like wind and seismic activity. This data informs the design of the bridge's beams and supports. - Support Placement:

The placement of supports is critical to distribute the load evenly and ensure stability. Engineers analyze the terrain, water currents (if applicable), and geological conditions to determine the optimal locations for piers or abutments. - Safety Considerations:

Designers must prioritize safety, incorporating guardrails, railings, and other protective features to prevent accidents and ensure user safety.

Beam Bridges - Construction Methods

- Precast Beams:

In many cases, the bridge beams are manufactured off-site as precast concrete or steel beams. These precast beams are transported to the construction site and lifted into place using cranes or other heavy equipment. This method reduces construction time and minimizes disruption to traffic.

Picture 2: Precast beam sections

- Cast-in-Place Beams:

For smaller bridges or when precast beams are not feasible, engineers may choose to cast the bridge beams in place. This involves pouring concrete into molds that are specifically designed for the desired beam shape. Cast-in-place beams can be more time-consuming to construct but offer greater design flexibility.

Picture 3: Bridge Beams

Types of Beam Bridge

Beam Bridge can be classified into many types based on four main criteria. They are as follows:

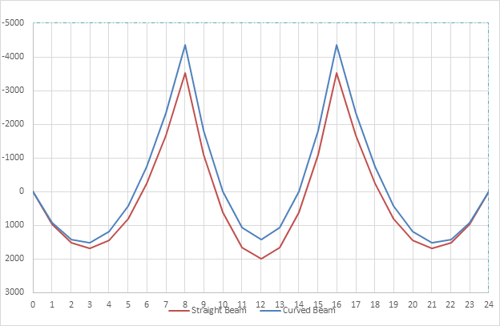

Based on geometry:

- Straight beam

- Curved beam

- Tapered beam

Based on the shape of the cross-section:

- I-beam

- T-beam

- C-beam

- Box

Based on the type of support:

- Simply supported beam

- Cantilever beam

- Continuous beam

- Fixed-beam

Conclusion

Beam bridges may seem simple, but they are essential components of transportation infrastructure. They are really an efficient structure for short & medium-span bridges.

Their design principles, choice of materials, and construction methods are critical factors in ensuring their safety and longevity. Therefore, these aspects should be properly considered to provide reliable and cost-effective solutions for crossing various obstacles in our built environment.

Add a Comment