BrIM: Does 3D help rebar detailing ?

Author: MIDASoft

Publish Date: 20 Dec, 2021

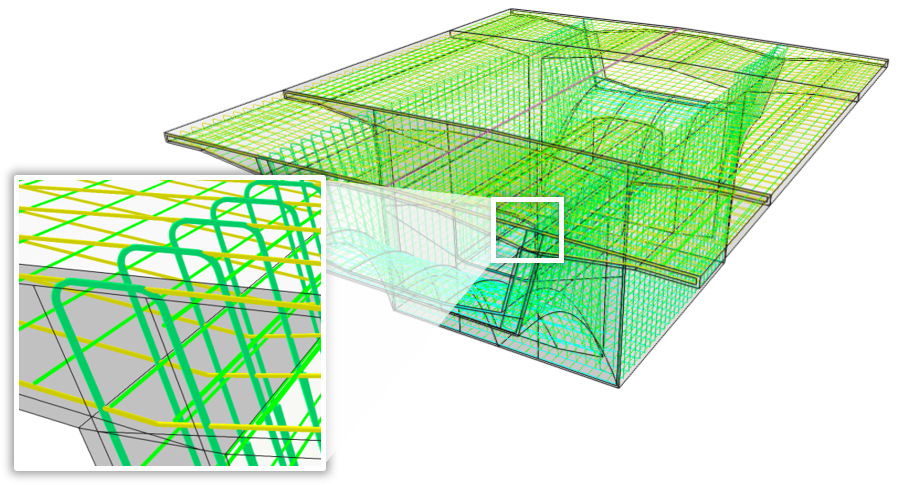

Rebar design is critical in a structural project with concrete because it determines not only structural integrity but also the cost of the project. In the current market, most structural engineers communicate with other contractors using the 2D drawings of rebar layout. However, It is difficult to

conceptualize the rebar arrangement in 2D. A big portion of construction RFIs deal with rebar conflict at the site, and it causes delays and increases in cost. 3D can be a significant advantage to catch this issue beforehand and eliminate unnecessary RFIs.

What is the reason hindering engineers from using 3D for rebar? Some of the issue engineers mentioned were a 3D model not being the requirement, people and firms are equipped to handle the issue conventional 2D method. Among the reasons, one thing that stood out most was the time and effort they put into initial modeling is too much for what they get. In midas CIM, the focus of the rebar modeling was to make it easy for anyone to use it. The rebar wizard equipped with a different type of rebar details helps you easily layout the base in 2D. Once you created the 2D arrangement, you can array it throughout the 3D structure, whether it is tapered or not. Depending on the spacing and condition you set up, It will automatically adjust its detail based on the section plane rebar is placed. Also, It adjusts itself parametrically as concrete size or length changes. This concept will help you keep 2D CAD skills and easily expand your expertise to 3D.

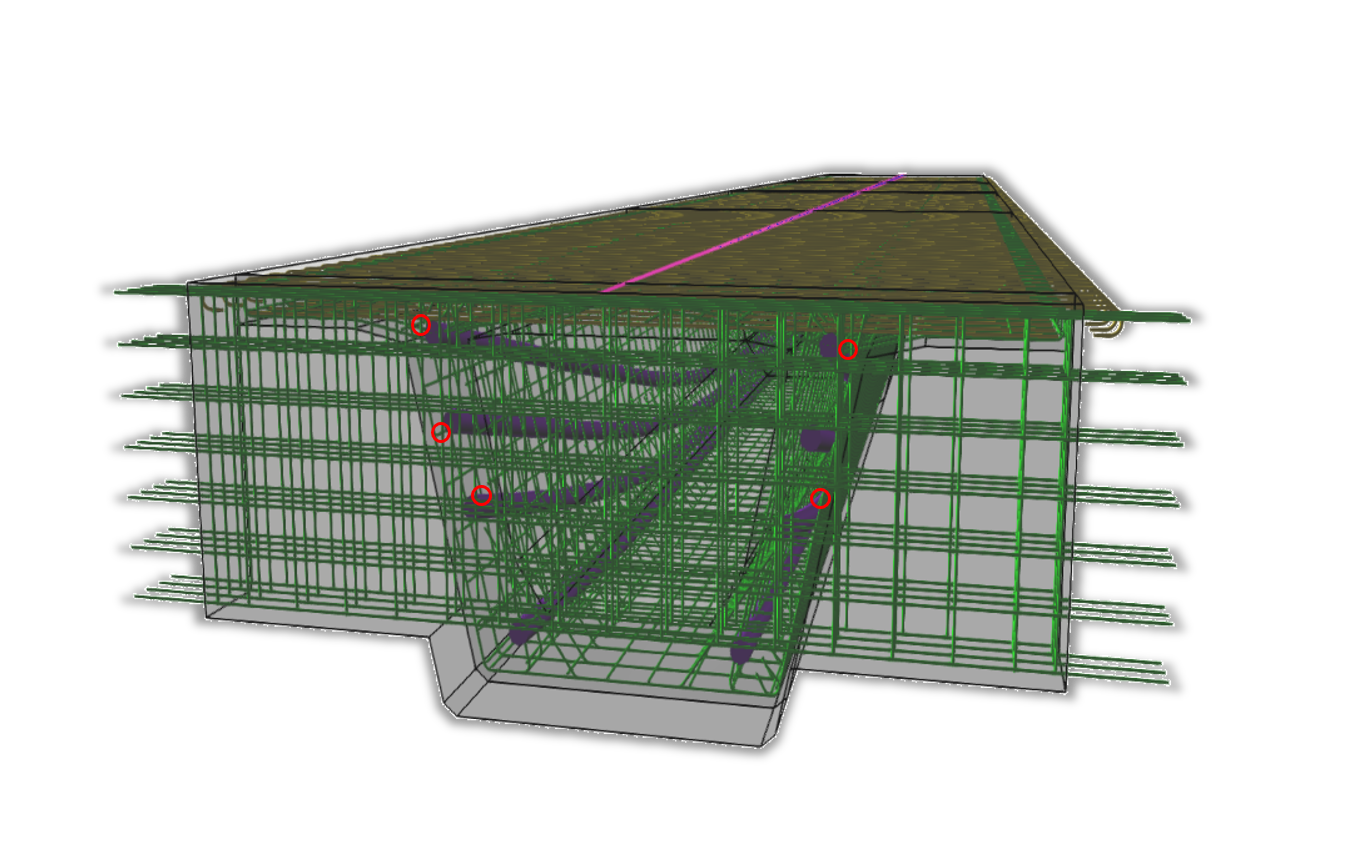

In complex geometry, The 3D rebar model will give you great benefit by detecting rebar conflicts before it is handed over to construction. 3D CAD-based program will also help you quickly adjust those identified conflicts and still check the structural integrity. It can also be expanded to the detection of conflict in different materials such as tendon, bolt, anchorage, cable, and so on. It will significantly improve the construction phase by preventing back and forth communication for RFI.

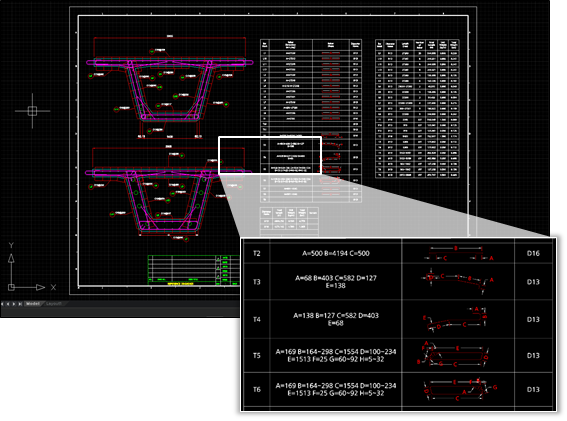

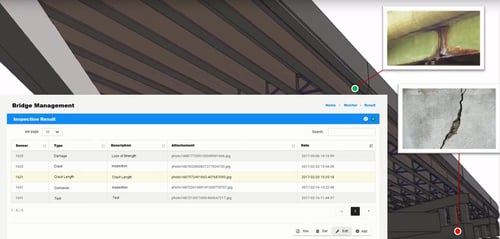

Is there other benefits of a 3D model for rebar? The BrIM as the name suggests, contains information inside of the geometry. This means not only the 3D model can be regenerated into 2D Drawings, but It can also be generated into rebar quantity report and bending schedule. This will remove the time spent on the post-processing of rebar design and offset the time you will be putting in the initial model. A bill of material from the 3D model can be generated into an excel to be utilized for the report or cost estimation. 2D drawing production will reduce a significant time for finishing up the deliverable for project requirements. Midas CIM aims to deliver a smooth 3D modeling experience with outputs that can help engineers. As the Bridge industry is quickly adopting 3D technology, it is crucial to develop tools that can accommodate the need for engineers in the field.

If you wish to try this complete rebar features in 3D with midas CIM please click below

Add a Comment