Steel & Post Tension Straddle Bent Design & Analysis

Author: Mir Hadi Ali, Annus Ahmed

Publish Date: 6 Dec, 2018

S U M M A R Y

Modeling Steel straddle and post-tensioned Bent has been always a challenge to

By using multiple software and spreadsheets, engineers were able to achieve a complete design for a Straddle

Therefore, Midas and Stantec prepared this webinar to help engineers to overcome those difficulties.

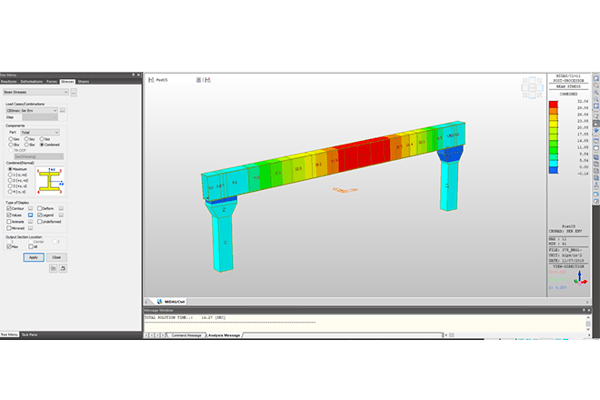

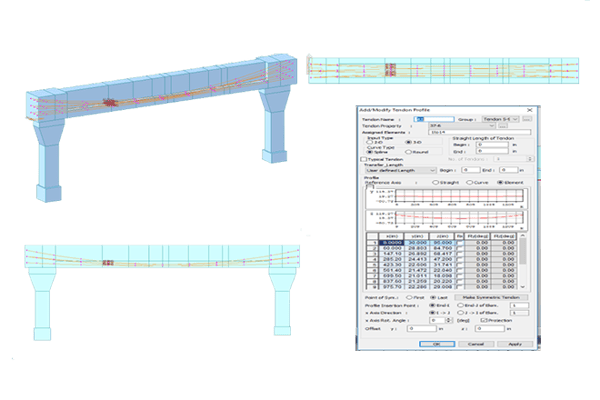

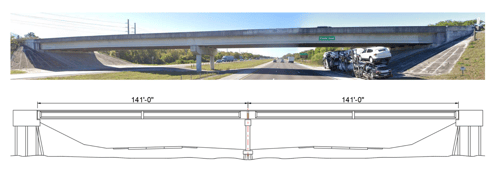

In this project, you will see how Mr. Ali and Mr. Ahmed managed their steel straddle

and post-tensioned Bent from the modeling, design, and staged construction analysis using Midas Civil.

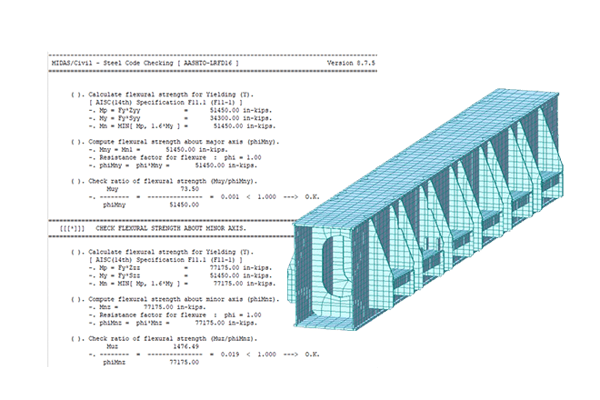

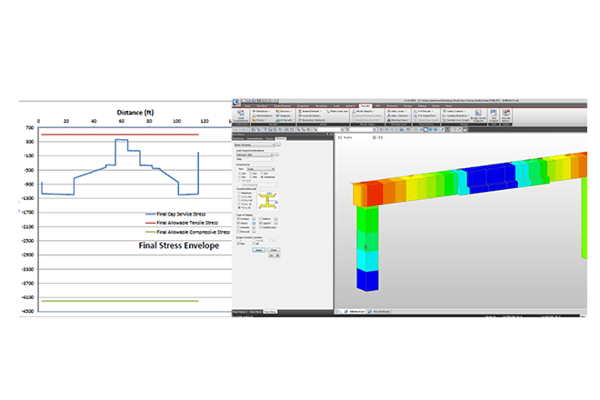

1. Modeling and structural analysis for Steel and Post-tensioned straddle bent.

2. Staged construction analysis for optimizing the design based on the hauling and lifting capability

and availability of material.

3. Benefits of using an integrated model for the design and analysis where the sub and

Q&A

At the end of the recording, the speakers addressed the following questions raised by the participants.

- How is meshing done on the steel cap (mesh size)? Did you use some tool outside MIDAS for the meshing?

- Is the box steel cap modeled with plate element instead of beam element? If so, does MIDAS have the ability to design the steel cap modeled with the plate elements?

- Can you provide more details on how these loss values verified (relaxation, creep, )?

- If MIDAS didn't have the TXDOT prestress loss option yet, how is the prestress loss considered in the model? Did you calculate the losses outside MIDAS and then enter in the losses for each stage?

- As part of the QA/QC, you mentioned that different software programs are to be used. Use of various programs is by the same engineer or is it by two different engineers?

- What was the diameter of hinge reinforcement at the interface of the precast cap to columns to create a hinge?

- How was foundation stiffness considered in the model?

- For the deep steel straddle caps, did you evaluate a temperature gradient?

- For tub girders, did you check how MIDAS calculate the torsional rigidity for the non-composite/ composite state?

- What is the difference in modeling rectangular inverted T section in concrete PT?

- How Midas get AASHTO Service III load combination while there are construction steps?

- How did you estimate distortion in the steel box if you only used a 2-D model?

- What was the temperature gradient you used for the exposed and shaded portions of the steel straddle cap?

- Does TxDOT require the difference in the EOR and ICE to be less than 5% even on the DB projects?

- What boundary conditions did you assume between the girders and the bent cap?

- What type of deck joints were used at straddle bents?

- How does the independent design check affect the construction schedule?

| |

Speaker : Mir Hadi Ali, Annus Ahmed Email : Annus Ahemd - annus.ahmed@stantec.com Category : Bridge Software : midas Civil Date : 2018-12-06 |

Add a Comment