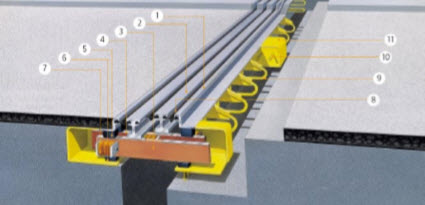

WSG-Type Modular Expansion Joints

Author: Luciana Farias

Publish Date: 4 Sep, 2019

A study into the structural behaviour of modular expansion joints of Sollinger Hütte

Hendri Koop

"Abstract

Expansion joints are applied in bridge structures to provide a smooth transition between the abutment and the superstructure of the bridge for traffic and to enable movements of the bridge structure. For long span bridge structures mainly joints belonging to the family of modular expansion joints are used in the Netherlands. The basic concept of modular expansion joints is over 30 years old and consists of center beams placed in transverse direction of the bridge supported by beams in traffic direction. Nowadays there are several manufacturers with their own variations in design to the basic concept. For historical reasons, many bridges in the Netherlands are equipped with joints made by the German company Maurer Söhne GmbH & Co. KG. Recent graduation works at TU Delft elaborated on joints produced by this company. Another German company that produces modular expansion joints is RW Sollinger Hütte GmbH. Their type is produced under the name “WSG Lamellen-Dehnfuge” and has been applied in Bridge Heteren, which is subject of a case study during this research.

Current design and construction is based on many years of experience and simple two-dimensional line models, and the dynamic behavior is often determined with over-rolling test. The joints however have a strong three-dimensional behavior. This research has been performed in order to obtain a better understanding of the structural behavior of WSG-type modular expansion joints made by Sollinger Hütte. Therefore, analytical calculations and a numerical analysis were performed. The analytical calculations have been made according to Annex G of the “Guideline for European Technical Approval of Expansion Joints for Road Bridges”, which is composed by the “European Organisation for Technical Approvals”, as it was at the end of 2006. For the numerical analysis a finite element model of the WSG 320-joint was constructed. The manufacturer has provided the necessary information about the WSG-type joints of Bridge Heteren and the finite element model was made with the use of the analysis program MIDAS/Civil.

For this analytical analysis a simple two-dimensional model has been used in which the traffic load was placed at the most unfavorable position without taking the distribution of traffic lanes into account. Verification of the static strength has shown that the center beams, support bars and support bar bearings have sufficient capacity to withstand the traffic loads. The values for the unity checks already gave reason to expect that the support bar would be the governing structural element for the fatigue life of the expansion joint. The field of one of the support bars was therefore one of four cross-sections of the structure for which the fatigue damage and the fatigue lifetime has been determined as part of the fatigue assessment with Fatigue load Model 2 (FLM2EJ) of Annex G, equivalent to EN 1991-2 FLM 4. The results indicate a more unfavorable behavior than the original design calculations that showed no fatigue damage within the design lifetime of 30 years. By studying the influence of the partial fatigue strength factor it has been shown that regular inspection and maintenance are very beneficial with respect to ensuring a long lifetime.

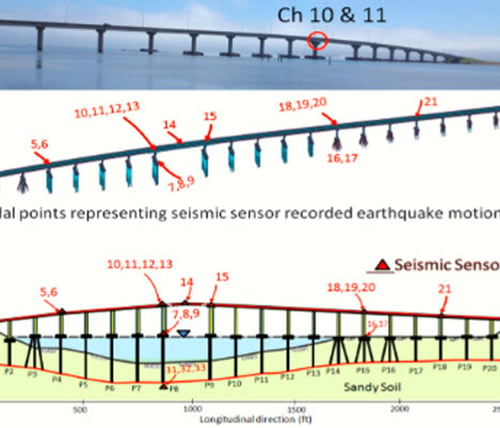

While establishing the finite element model of the WSG 320-joint for the numerical analysis some aspects were recognized that are relevant to consider during the pre-processing phase. First of all modelling the axle loads needs to be done very accurate, but depends on the detail level at which the structure is modeled. Refining the mesh of those elements that form the contact surface allows a better description of the load functions. Furthermore it is noted that for the moment modelling of the friction between sliding plates is difficult to achieve with the analysis software used. First a reference model was made for the situation of Bridge Heteren, which is more or less an exceptional situation. Therefore a modified reference model was established which is more in line with current design practice.

The numerical analyses for the reference model and the modified reference model, produced results that lead to a clear view on the structural behavior of the WSG-type expansion joint. The most relevant results are as follows: - The frequency analysis showed that although low values are found for the first natural frequencies compared to those found in literature, the modes that govern the system behavior have higher frequencies (> 132,8 Hz for the vertical motion);

- Dynamic properties of the control spring and the length of spans for center beams are important for the dynamic and fatigue behavior; - Table 1 and 2 shows dynamic amplification factors found. The reference model leads to higher values than those included in the fatigue loads of Annex G. The modified reference model gives factors that are more favorable for the vertical and worse for the horizontal loading; - When a situation with vertical and horizontal loading is considered, a phase shift can occur between the time points of maximum amplification for each load directions. If this happens the governing phase combination must be applied in the fatigue analysis of a center beam; - Comparison of a fatigue analysis for both models shows that the modifications taken into account in the modified reference model have a positive influence on the fatigue behavior.

Table 1 Dynamic factors for the reference model (Bridge Heteren).

Wheel print 300 x 300 300 x 300 400 x 400 Force direction Vertical Vertical Horizontal Vertical Vertical First dynamic amplitude 2.1 1.9 3.0 1.6 2.1 Upswing ratio 1.2 1.1 1.2 1.2 1.0 Dynamic interval 2.5 2.1 3.7 1.8 2.2 Support bar 400 x 400 Center beam

Table 2 Dynamic factors for the modified reference model.

Wheel print 300 x 300 300 x 300 400 x 400 Force direction Vertical Vertical Horizontal Vertical Vertical First dynamic amplitude 0.7 0.8 1.1 1.1 1.4 Upswing ratio 1.0 1.1 1.3 1.2 1.2 Dynamic interval 0.7 0.8 1.4 1.3 1.7 Support bar 400 x 400 Centre beam

The research has lead to recommendations concerning modular expansion joints and fatigue. In short the recommendations that are considered most important are: - Investigate the structural behavior of larger WSG-type modular expansion joints of SollingerHütte that can cope with much larger translations than the WSG 320-joint, as these joints almost completely rely on friction between components; - Study a modular expansion joint with a similar construction principle from another producing company. Subject could be for example the Tensa modular type LR made by Mageba; - It is recommended to study the dynamic characteristics of the control springs in order to obtain more accurate values for the different stiffnesses; - It is recommended to study the effects of the actual traffic data in comparison to the traffic data as presented in the standards. If this is done there will be a more realistic expectation about the fatigue life of the expansion joints.

For future calculations on the WSG-joints of Bridge Heteren the modelling presented in this study can be applied. However, it is advised to keep in mind that the axle load has been placed at the most adverse position without considering the distribution of the traffic lanes."

Add a Comment