Midas Civil: Segmental Construction - Helicoidal Bridge

Author: Edgar de los Santos

Publish Date: 15 Jul, 2021

Project Name: Helicoidal Bridge

Location: Risaralda, Colombia

Company: Gregorio Rentería Ingenieros SA (GRISA)

Types of analysis used:

-Post-tensioned analysis

-Dynamic nonlinear analysis

-Seismic isolators

Program used: midas Civil, MIDAS 'integrated solution for bridges. Learn more

Length: 1,296 ft.

Diameter: 590 ft.

Year of inauguration: 2010

Project Description

The Helicoidal Bridge is part of a road with a total of 3.5 kilometers, of which 125 meters are tunnels and 395 meters of the bridge. The bridge is 1296 ft long with a diameter of 590 ft. The bridge is mounted-on friction pendulum seismic isolators that allow the displacement of the superstructure in an earthquake or due to temperature changes.

As a solution to the instability of the slopes and the height difference, an alignment was designed, including a geometric helical figure, like the spiral of a spring.

The bridge has seven spans at 164 ft and 2 terminal overhangs at 92 ft. It has two abutments and eight hollow circular piers. Two have a 10.5 ft in external diameter and for the tallest pier on each slope and 7.55 ft in diameter for the remaining piers. The height of the piers varies between 15.8 ft and 84 ft.

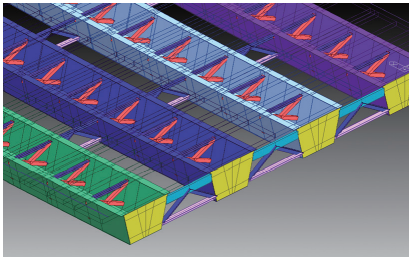

The post-tensioned concrete box girder has a 33 ft wide deck and a constant section height of 7 ft. It has a 7% gradient and 8% superelevation. The elevation of 125 ft makes it possible to take to the mountain ridge to travel practically to the back of the hill.

Figure 1. The portal of a curved tunnel leading to the helical bridge.

Determining Factors

- Unstable soil, composed of volcanic ash and residual materials.

- Impossibility of expanding the existing road.

- The minimum intervention of the terrain guarantees the stability of the road alignment.

- The bridge was selected from several alternatives due to the safety it represents since it did not require a significant intervention on the ground, which does not present excellent stability due to geographical conditions.

- In addition, the work does not register high environmental impacts and represents more excellent long-term stability.

Construction Process

The construction methodology chosen for this project is that of balanced cantilever segmental construction, which is carried out through form travelers, installed on the surface of the slab of the support beams.

A form traveler formwork system is mounted with a crane that allows the first segment to be poured, which after setting is tensioned. To install the second traveler, the first must move on to the already poured segment. The construction of the segments is made symmetrically on the column; the length of the cantilever depends on the design specifications. In this project, four travelers were used to speed up the splicing of the cantilevers.

Figure 2. Formwork traveler

This project was of high risk, which the builders and designers assumed because of such high gradient, superelevation, and radius of curvature. It was possible thanks to strict construction and quality control protocols.

Before putting the bridge into operation, the road had traffic records of up to seven thousand vehicles per day, mostly heavy vehicles, with average operating speeds of less than 13 miles per hour. Therefore, any problem on the road generates significant traffic jams.

The proposal that has been built makes it possible to improve the level of service and increase road capacity, with a dual carriageway with two lanes in each direction, as opposed to what was thought of two two-way carriageways each.

Additionally, 'inverted pendulum' type seismic isolators were used, a state-of-the-art technology that creates a structural discontinuity between segments and support, using a mechanism in which two concave surfaces meet. This allows the bridge to 'float' on the seismic isolators in the event of a seismic movement. In other words, the energy of an earthquake is not transmitted to the superstructure, and it is freed from this requirement.

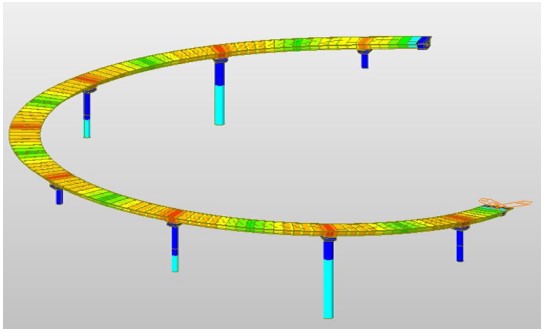

Figure 3. Helicoidal Bridge

Project Application in midas Civil

Figure 4. Midas Civil render (Isometric view)

Figure 5. Helicoidal Bridge

References:

- https://www.elespectador.com/colombia/mas-regiones/uribe-inaugura-el-puente-helicoidal-en-pereira-article-213896/

- Construdata magazine edition 159 Jun – Aug 2011

- https://vimeo.com/29756079

Add a Comment