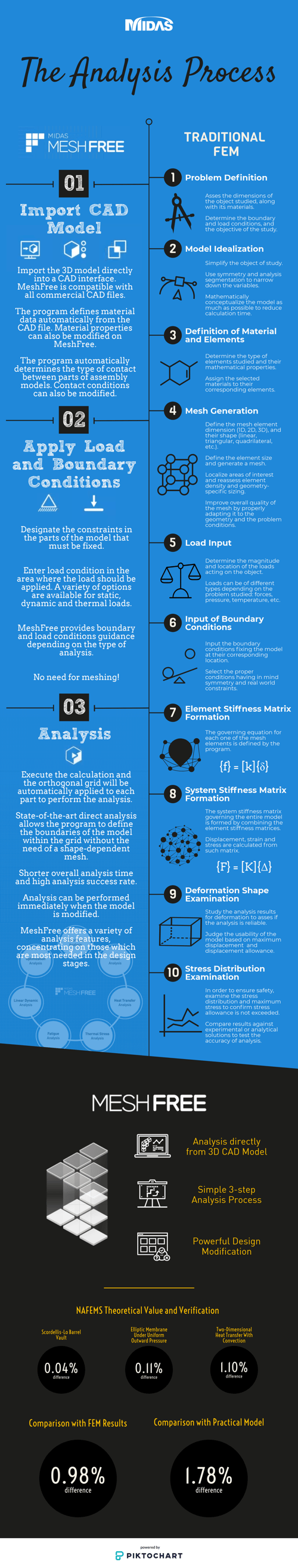

Midas NFX: The Future of Finite Element Analysis: MeshFree

Author: Gabriel Roade

Publish Date: 27 Dec, 2021

The Future of Finite Element Analysis

From the beginning of civilization to this very day, men and women of this Earth have tried to make sense of the world. A relentless effort to find order and stability in a world oftentimes unpredictable and of mesmerizing complexity has driven us to the development of a systematic deconstruction and analysis of nature, a study we have come to call science.

Among the many branches this generous tree of empirical knowledge has come to grow, there is one that has become the epicenter of today’s technology and overall standard of living: engineering.

From cars to washing machines, smartphones to spaceships, along with the endless possibilities of artificial intelligence and robotics, we are surrounded by the flavorful fruits of engineering. Technology is at the core of our life, and the pioneers responsible for the great feats we so regularly enjoy these days are now prouder than ever to call themselves engineers. There was once an era of knights and damsels, then came an era of explorers and scientists, and now we live in the era of engineers and inventors.

The first engineers had the difficult task of breaking down the most fundamental principles in nature and applying them to the construction of the first technological wonders, and they did so with their bare hands. Soon enough, those bare hands were filled with the tools they had built.

Engineering is a field that, like all sciences, exponentially improves upon improvement: the first table was built with the saw, the hammer and the nail, upon a table was drawn the blueprint for the first computer, and it is a computer that allows us today to design the most riveting inventions and simulate their behavior before even constructing them.

Simulation is the key to a good, efficient and cheaper design. Simulation allows the engineer to test their theories and assumptions with the help of revolutionary mathematical theories for analysis and the tremendous computational power of today’s software and hardware, and to do so without the expense of material and manufacture a physical prototype would require.

The great advancements in electronics and electronics packaging has created the hardware necessary to support simulations, but how does simulation software work?

Computer-aided engineering simulations are mainly based on the finite element method (FEM). The finite element method is a numerical method that allows solving complex engineering and mathematical problems by breaking down an object of study into simplified elements that can be modeled mathematically.

The mathematical models for most of physical phenomena and engineering mechanics are built using partial differential equations (PDEs).

Engineering-related PDEs are specially complicated equations that output exact theoretical measurements of relevant characteristics in a structure (stress, strain, deformation, temperature, etc.), from which a simulation of the real behavior of the design under a set load can be made.

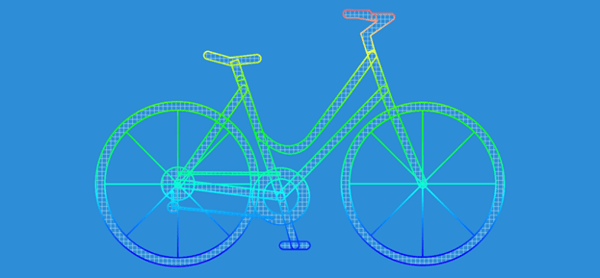

Finite element analysis (FEA) gives an approximation to the solution to these problems by numerical approach. By this approach, the shape of the object of study is broken down into a great number of small simple elements, creating a net of elements called mesh. The computer runs calculations for every single element in the mesh and then adds the individual results in accordance with the correlation between these elements, usually having to use interpolation to make the disparity in results between connected elements agree.

Since a shape is rarely of uniform geometry, different parts of an object, and objects of different geometry, will need different methods of defeaturing, or simplification of shape, to create an accurate mesh.

The process by which these different meshes are made and added together is called mesh generation or meshing, which has become one of the most important and least standardized processes in current engineering design. To properly choose what method of meshing to use and where, an engineer must have a deep understanding of the different types of shapes and how the software reads them, a knowledge hardly attained from any source but the engineer’s own experience and intuition.

Moreover, different software will have different meshing features and computational approaches, making it harder for the engineer to make the shape and the mesh agree if they are not familiar with the program.

The main difficulty in meshing comes from its shape-dependent nature.

Current FEA software focuses the mesh process on the coordinated arrangement of linear elements. Therefore, curved and complex surfaces must often be simplified, a process called defeaturing, to accomplish an accurate mesh. A more precise mesh needs either more elements, which requires more computational time, or more defeaturing, which outputs less accurate results.

The balance between too many elements and too much defeaturing is at the core of the design engineer’s decision making. Sizing specific parts that are focus of the analysis or that have especially singular shapes, knowing what sections require less elements, and creating, by trial and error, an overall mesh of good quality are the main tasks for engineers using FEA.

Meshing has become the main task design and analysis engineers spend most of their time on.

This is the present of FEA practice and design engineering. However, what if the network of elements was not shape-dependent anymore?

What if all those hours of creating and improving a mesh were not necessary to get accurate results? What if there was a way to use the same network of elements even after modifying a design? What if there was a program where you could upload a CAD model and set the boundary conditions and the computer did the rest?

What if a mesh-free future was possible?

And what if the future was already available?

Midas MeshFree is the answer to all those questions, and that answer is a rotund and solid yes.

Yes, MeshFree creates a network of elements that is not shape-dependent; the program uses structure orthogonal grids that are independent of the boundaries of the analysis model and that simply divide the space occupied by the model.

Yes, all those hours of meshing are unnecessary when using MeshFree, since the program does not need of any meshing process prior to computational analysis.

Yes, once a grid has been created for a specific analysis case, the model can be modified and updated without the need of creating a new grid.

Yes, there is a program where you can upload a CAD model, set the boundary conditions and let the computer run all the calculations: MeshFree.

The revolutionary algorithm that allows MeshFree to perform an analysis without the need for meshing is based on the combination of regular FEM and a variation of the Dirichlet function.

The Dirichlet function becomes zero when reaching a boundary, which allows the algorithm to mathematically map a shape when integrating for the area volume.

Therefore, grid blocks completely within the shape, since they do not meet the boundaries, will be analyzed using the traditional FEM formulation, but those grid blocks in which the boundaries of the shape are contained will be analyzed in proportion to their Dirichlet function, which describes the limits of such boundaries.

Traditional FEA would use defeaturing to create a mesh of nodes onto the area of a shape so that boundary conditions may be applied on those nodes, while MeshFree is able to set boundary conditions both on the nodes within the shape and on the boundaries found by the Dirichlet function.

The application of boundary conditions in MeshFree is independent of nodes.

MeshFree has been developed by Midas IT, a leading company in civil and mechanical engineering software, in collaboration with Samsung Electronics.

The concept of a program capable of accurately analyzing 3-dimensional shapes without a mesh generation step sprung from the necessity for a software that did away with the inefficiencies of traditional methods and allowed engineers to focus on more valuable tasks and engage in a more creative process. MeshFree is easy to use and intuitive, allowing engineers and non-engineers with any level of experience in FEA to take advantage of the great simulation power of today’s computers without needing to learn how to mesh properly.

And you can get a free version of MeshFree today!

Let the computer worry about all the analysis and calculations and focus on creating a beautiful, innovative and efficient design.

Be part of the future of finite element analysis.

| |

Speaker : Gabriel Roade Category : Mechanical Software : midas MeshFree Date : 2018-08-06 |

Basis function

Add a Comment